– by Deborah Rogers –

While manufacturing across Canada has seen a decline in the past decade, the Saanich Peninsula tells a story of successful investment, development and training that has created a strong commercial sector right within our community. Quietly providing millions of dollars in payroll to the workers of our local economy each year, the industrial area around Victoria airport and Keating Cross Road is alive, well and growing all the time.

It may surprise you to learn that on southern Vancouver Island there are 120 manufacturing businesses, and over half of those are located within the three municipalities that make up the Saanich Peninsula. Between them they have a combined revenue of over $1 billion annually. How is it that so much industry exists within our community, and why aren’t these local businesses all household names?

There’s a reason why the million-dollar industries of Quester Tangent, Schneider Electric or Redland Technologies aren’t always top-of-mind when thinking about locally-made products as these businesses are primarily exporters. We’re not using the products made by Scott Plastic, Viking Air or SeaStar Chemicals in our day-to-day lives. If you’re a mountain biker though you may have (or aspire to have) some of the high-end aftermarket bike components made right here in Sidney by Straitline Components. A house brand of Straitline Precision Industries, DJ Paulson describes the success of these “fully in-house manufactured mountainbike components sold worldwide through broad reaching distribution channels.” These include pedals, stems, sprockets and chainguide devices with “many top athletes worldwide utilizing these products to push the limits of the sport.”

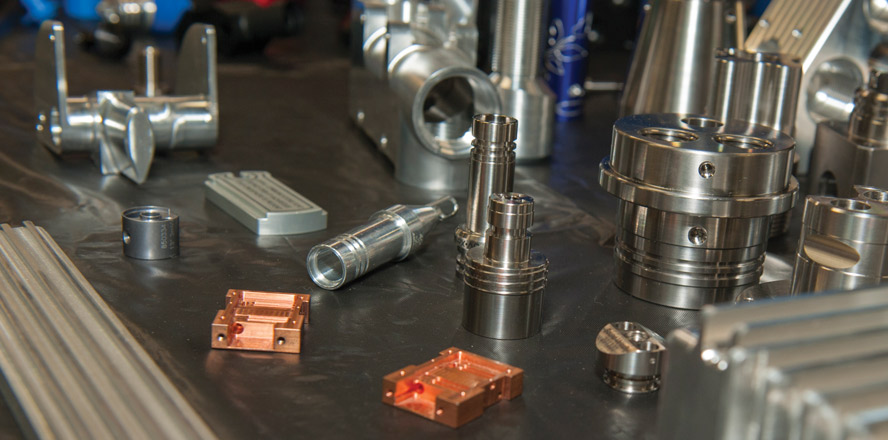

Currently employing 10 people at their Sidney facility, Straitline Precision Industries is a high precision CNC manufacturing facility with a diverse range of capabilities for servicing the Aerospace, Medical, and Industrial Equipment sectors. Founded in 1996 by DJ, his brother Dennis and their father Mike Paulson, they stress a strong emphasis on supplying the absolute highest standards of quality and workmanship to their customers. “Over the years we have successfully maintained this reputation and have many customers throughout the world.”

Now fully certified, this machine shop is supplying high-spec aerospace components. “We manufacture a multitude of Flight Critical components for the Viking Air Twin Otter program, and service many other industries including oceanographic relocation devices, GPS location housings and Electronic Co-ax Connectors, as well as a variety of medical device development companies.”

Being based on Vancouver Island hasn’t stopped them from building a worldwide customer base. “There are many great companies here on the Peninsula that produce economic benefit for our local economy. Many of these companies need contract manufacturing services and we are right here at their doorstep. Since we are local to these companies it gives us the advantage of being able to work more closely and often even in person, with our customers,” says DJ. But he concedes that the perception of higher shipping costs from Vancouver Island can be a disadvantage.

Just up the road from Straitline’s established machine shop is a brand-new manufacturing business. There’s a constant background hum while I talk to Warren Strome, owner of Revolution 3D Printers, with multiple 3D printers working away producing parts that Warren will later piece together to make more printers. Still in the process of setting up his new Sidney premises, Warren told me how he ended up being Sidney’s newest manufacturer. Initially born from a personal interest, this company has taken a new technology and is capitalizing on the excitement about its potential. Through experimentation, Warren has developed a high-quality product made with a combination of components brought in from across Canada and the U.S., but also around 35 of the parts are manufactured in-house by their own printers. With huge potential sales to schools and colleges as well as small-scale R&D facilities, Revolution 3D Printers has the potential to scale up their manufacturing to meet demand. Warren spoke about the possibility in the future of making local connections to produce components down the street: “This is what this type of manufacturing is intended to do, to bring manufacturing back home. We could go offshore but the understanding is that there’s a high North American standard we’d like to achieve.”

It’s small-scale production at the moment, but interesting to have another manufacturer in the Airport Industrial zone. There are always barriers to growth with economic factors like fluctuating currency and new trade deals on the horizon, but there are also local factors that will affect the growth of this industry, such as affordability of housing and finding workers with the right set of skills for the specialized jobs.

However, Federal government money is available to help with some of these issues. I spoke with John Juricic of the Vancouver Island Manufacturing Sector Advisory Board who described southern Vancouver Island as having the potential to become “a Silicon Valley North for manufacturing” with the infrastructure ready-built and so many highly-skilled people in place. By focusing on soft skills training like innovation, creativity and change management, he hopes some of the barriers to growing manufacturing will be removed.

With High School Trades programs and an excellent training and Applied Research and Innovation department at Camosun, there is real enthusiasm for manufacturing as a career. The promise of jobs on the doorstep is an incentive for students to pursue the necessary skills.

From the likes of Viking Air manufacturing the Twin Otter aircraft, to smaller machine shops like Straitline Precision Industries right through to brand new businesses like 3D Revolution Printing, there is a wealth of design and manufacturing expertise within our community. A positive economic story, manufactured right here on the Saanich Peninsula.

Photos by www.nuttycake.com.